INTRODUCTION

Before going to main topic, we should know what is electrical motor. Electrical Motor is an electromechanical device that converts electrical energy into mechanical energy. An Induction machines is basically Asynchronous machines. If the Induction Machine converts Mechanical energy to Electrical energy, then it is called Induction Generator. If the Induction Machine converts Electrical energy to Mechanical energy, then it is called Induction Motor.

In the case of three-phase AC (Alternating Current) operation, the most widely used motor is a 3 phase induction motor, as this type of motor does not require an additional starting device. So, these types of motors are well known for self-starting induction motors.

A single Phase induction motor is self-starting. There is need of separate starter for it

The induction motor may be considered to be a transformer with a rotating secondary and it can, therefore, be described as a “transformer type” a.c. machine in which electrical energy is converted into mechanical energy.

THREE-PHASE INDUCTION MOTOR

Like an electric motor, a 3-Phase induction motor has a Stator and Rotor. the stator carries a 3-Phase winding(stator winding) while the rotor carries a short-circuited winding(rotor winding). unlike a dc motor where both stator winding(field) and rotor winding(armature) are connected to a voltage source, the stator winding of 3-Φ induction motor is fed from 3-Φ supply. The rotor winding derives its voltage and power from the externally energized stator winding through electromagnetic induction.

Advantages:

- It has simple and rugged construction.

- It is relatively cheap

- It requires little maintenance.

- It has high efficiency and reasonably good power factor.

- It has self-starting torque which is better than single phase.

Disadvantages:

- It is essentially a constant speed motor and its speed cannot be changed easily.

- Its starting torque is inferior to dc shunt motor.

- Speed decreases with increase in load.

CONSTRUCTION

A 3-Phase induction motor has two main parts-- Stator

- Rotor

Stator:

- Stator consists of a steel frame which encloses a hollow, cylindrical core made up of thin laminations of silicon steel to reduce eddy current losses. A number of evenly spaced slots is provided on the inner periphery of the laminations.

- Stator carries 3-phase winding and is fed from a 3-phase supply. The 3-phase stator winding is wound for a definite number of poles as per requirement of speed. Greater the number of poles, lesser is the speed of the motor and vice-versa.

- When 3-phase supply is given to the stator winding, a rotating magnetic field of constant magnitude is produced. This rotating field induces currents in the rotor by electromagnetic induction.

Rotor:

The rotor, mounted on a shaft, is a hollow laminated core having slots on its outer periphery. The winding placed in these slots (called rotor winding) may be one of the following two types:

- Squirrel cage type

- Wound type

Squirrel cage type:-

- It consists of a laminated cylindrical core having parallel slots on its outer periphery. One copper or aluminum bar is placed in each slot. All these bars are joined at each end by metal rings called end rings .This forms a permanently short-circuited winding which is indestructible.

- The rotor is not connected electrically to the supply but has current induced in it by transformer action from the stator.

- Those induction motors which employ squirrel cage rotor are called squirrel cage induction motors.

- Most of 3-phase induction motors use squirrel cage rotor as it has a remarkably simple and robust construction enabling it to operate in the most adverse circumstances.

- It suffers from the disadvantage of a low starting torque. It is because the rotor bars are permanently short-circuited and it is not possible to add any external resistance to the rotor circuit to have a large starting torque.

The rotor slots are usually not quite parallel to the shaft but are purposely given a slight skew. This is useful in two ways:

- It helps to make the motor run quietly by reducing the magnetic hum and

- It helps in reducing the locking tendency of the rotor i.e. the tendency of the rotor teeth to remain under the stator teeth due to direct magnetic attraction between the two.

Wound type:-

- It consists of a laminated cylindrical core and carries a 3- phase winding, similar to the one on the stator.

- The rotor winding is uniformly distributed in the slots and is usually star- connected. The open ends of the rotor winding are brought out and joined to three insulated slip rings mounted on the rotor shaft with one brush resting on each slip ring.

- The three brushes are connected to a 3-phase star-connected rheostat. This makes possible the introduction of additional resistance in the rotor circuit during the starting period for increasing the starting torque of the motor.

- At starting, the external resistances are included in the rotor circuit to give a large starting torque. These resistances are gradually reduced to zero as the motor runs up to speed.

- The external resistances are used during starting period only. When the motor attains normal speed, the three brushes are short-circuited so that the wound rotor runs like a squirrel cage rotor.

|

| Wound rotor type induction motor |

PRODUCTION OF ROTATING MAGNETIC FIELD DUE TO 3-Φ CURRENTS

When a 3-phase winding is energized from a 3-phase supply, a rotating magnetic field is produced. This field is such that its poles do no remain in a fixed position on the stator but go on shifting their positions around the stator. For this reason, it is called a rotating Field.

Consider a 2-pole,3-phase winding placed 120° space apart. The three phases X, Y and Z are energized from a 3-phase source and currents in these phases are indicated as 𝐼𝑥, 𝐼𝑦 𝑎𝑛𝑑 𝐼𝑧.The fluxes due to these these currents are ∅𝑥,∅𝑦 and ∅𝑧.

Consider a 2-pole,3-phase winding placed 120° space apart. The three phases X, Y and Z are energized from a 3-phase source and currents in these phases are indicated as 𝐼𝑥, 𝐼𝑦 𝑎𝑛𝑑 𝐼𝑧.The fluxes due to these these currents are ∅𝑥,∅𝑦 and ∅𝑧.

- ϕₓ = ϕₐ𝑠𝑖𝑛𝜔𝑡

- ϕᵧ = ϕₐ𝑠𝑖𝑛(𝜔𝑡 − 120°)

- ϕ𝓏= ϕₐ𝑠𝑖𝑛(𝜔𝑡 − 240°)

- At instant 1, the current in phase X is zero and currents in phases Y and Z are equal and opposite. The currents are flowing outward in the top conductors and inward in the bottom conductors. This establishes a resultant flux towards right. The magnitude of the resultant flux is constant and is equal to 1.5 ∅𝑚.

- At instant 2, the current is maximum (negative) in ∅𝑦 phase Y and 0.5 maximum (positive) in phases X and Y.

- At instant 3, current in phase Z is zero and the currents in phases X and Y are equal and opposite (currents in phases X and Y are 0.866 × max. value).

- At instant 4, the current in phase X is maximum (positive) and the currents in phases Y and Z are equal and negative (currents in phases Y and Z are 0.5 ×max. value). This establishes a resultant flux downward.

Both ∅𝑚 and ϕₐ are same i.e. maximum flux due to any phase

The speed at which the rotating magnetic field revolves is called the synchronous speed (Ns).

Direction of rotating magnetic field

The phase sequence of the three-phase voltage applied to the stator winding is X-Y-Z. If this sequence is changed to X-Z-Y, it is observed that direction of rotation of the field is reversed i.e., the field rotates counterclockwise rather than clockwise. However, the number of poles and the speed at which the magnetic field rotates remain unchanged. Thus it is necessary only to change the phase sequence in order to change the direction of rotation of the magnetic field. For a three-phase supply, this can be done by interchanging any two of the three lines. The rotor in a 3-phase induction motor runs in the same direction as the rotating magnetic field. Therefore, the direction of rotation of a 3- phase induction motor can be reversed by interchanging any two of the three motor supply lines.

PRINCIPLE OF OPERATION

The operation of the motor can be explained as under:

(i) When 3-phase stator winding is energized from a 3-phase supply, a rotating magnetic field is set up which rotates round the stator at synchronous speed Ns (= 120 f/P).

(ii) The rotating field passes through the air gap and cuts the rotor conductors, which are stationary. Due to the relative speed between the rotating flux and the stationary rotor, e.m.f. are induced in the rotor conductors. Since the rotor circuit is short-circuited, currents start flowing in the rotor conductors.

(iii) The current-carrying rotor conductors are placed in the magnetic field produced by the stator. Consequently, mechanical force acts on the rotor conductors. The sum of the mechanical forces on all the rotor conductors produces a torque which tends to move the rotor in the same direction as the rotating field.

(iv) According to Lenz’s law, the direction of rotor currents will be such that they tend to oppose the cause producing them. The cause producing the rotor currents is the relative speed between the rotating field and the stationary rotor conductors. Hence to reduce this relative speed, the rotor starts running in the same direction as that of stator field and tries to catch it.

SLIP

We have seen that rotor rapidly accelerates in the direction of rotating field. However the rotor can never reach the speed of stator flux. If rotor is rotating at synchronous speed ,then there would be no relative speed between the stator field and rotor conductors, no cutting of flux by the rotor conductors and there would be no generated voltages, no induced rotor currents and, therefore, no torque to drive the rotor. The friction and windage would immediately cause the rotor to slow down. Hence, the rotor speed (𝑁𝑟) is always less than the suitor field speed (𝑁𝑠). This difference in speed depends upon load on the motor.

(II) the speed of the motor when the slip is 4% and

(III) the rotor current frequency when the motor runs at 600 rpm.

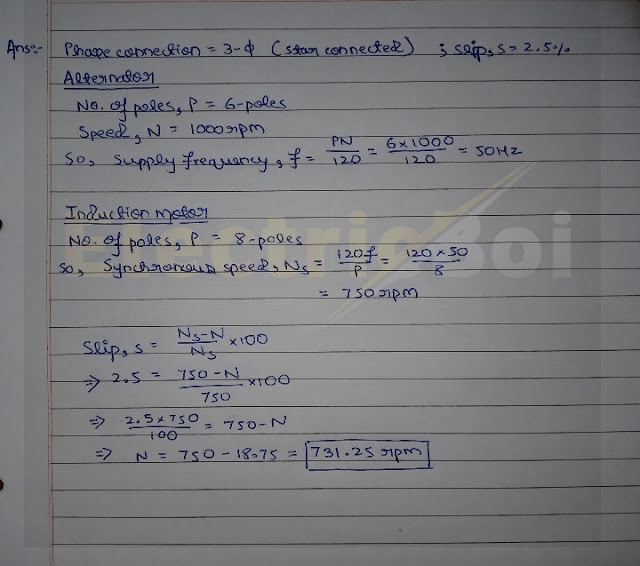

Example 3:- A 6-pole alternator running at 1000 rpm supplies an 8-pole induction motor. Find the actual speed of the motor if the slip is 2.5%.

Example 4:- A 50 Hz, 4-pole, 3-phase induction motor has a rotor current of frequency 2 Hz. Determine:- (I) the slip and

(II) speed of the motor.

on full load. The machine has 6 poles. calculate the full load slip. How many cycles will the rotor voltage make per minute?

Q1:- A 10-pole, 3-phase alternator is coupled to an engine running at 600 rpm. It supplies 3-phase induction motor which has a full-load speed of 1440 rpm. Calculate the number of poles and slip of the motor.

Stay tune with us :)

Any doubt/problem, let us know in the comment section below, we would love to read your comments :D

0 Comments